CNC MACHINING

We have extensive experience of advanced machining. We have a flexible and modern machine park, with machines programmed using a computer-aided manufacturing (CAM) system.

Our machines can manufacture components ranging in size from small to very large, with a lifting capacity of up to 12.5 tonnes.

We work with vertical 3-axis machines and horizontal 4 and 5-axis machines. For large structures and components, we have bed and floor-type milling machines.

Our machines

Floor-type milling machines

For machining very large components, we use a floor-type milling machine.

Our large floor-type milling machine has a working area of 14 x 4 x 1.5 metres and is equipped with a 2.5 x 2.5 metre rotary table and a milling head indexed to 0.001o on two axes to allow machining of oblique planes and holes. The machine’s size, flexibility and level of equipment mean that we can machine large, complex components with high precision.

Bed-type milling machines

For machining large components, we have state-of-the-art bed-type milling machines with working areas up to 4.5 x 2 x 1.2 metres. They are equipped with e.g. automatic tool changers, guided cutting heads and rotary tables.

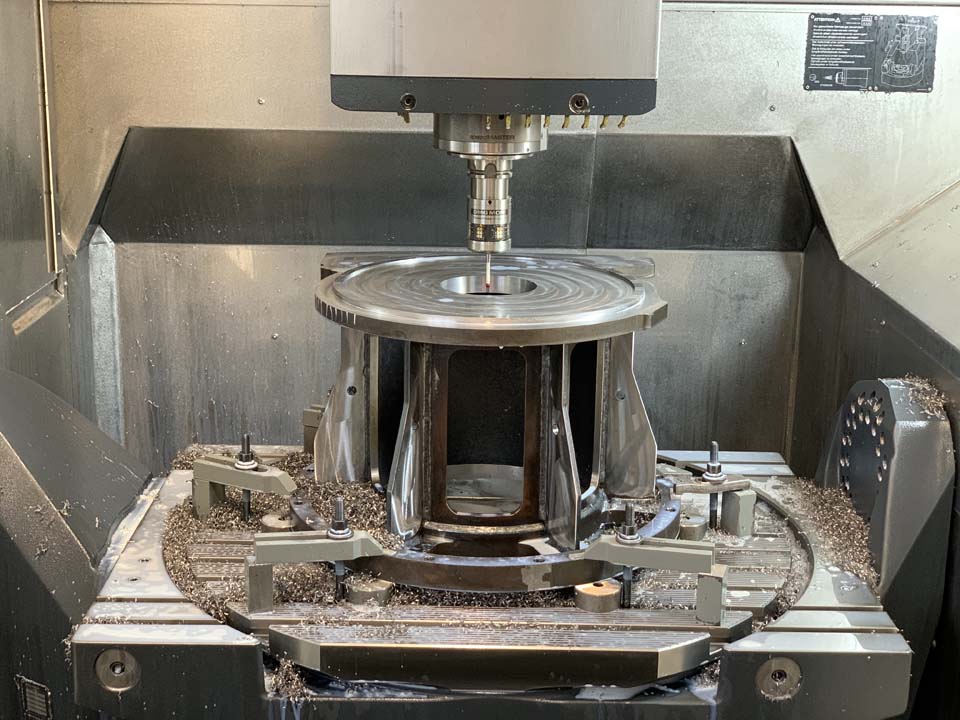

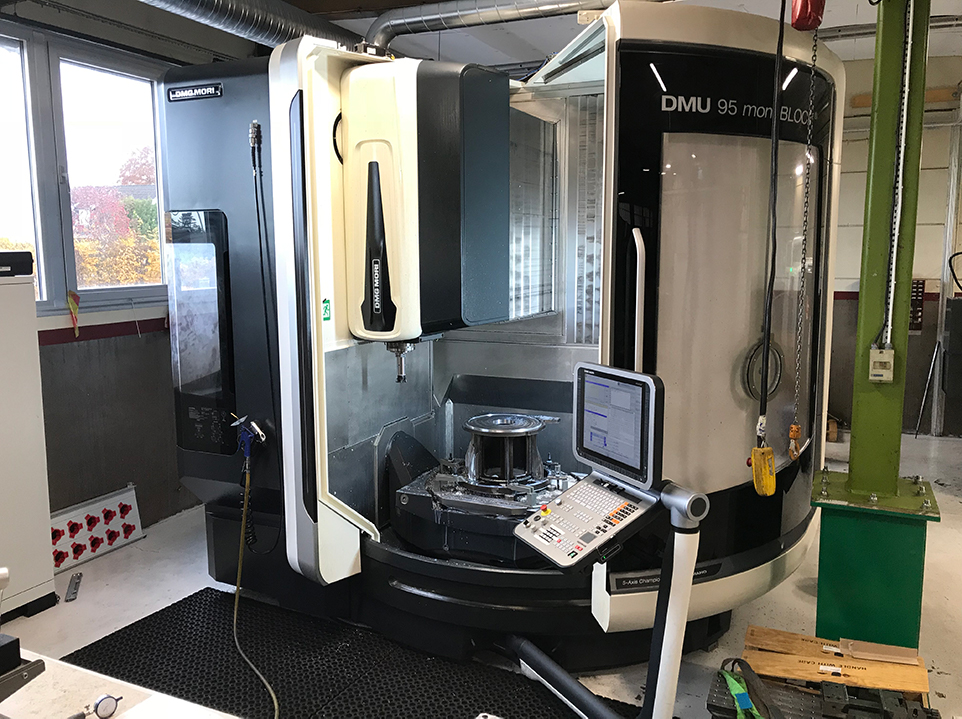

5-axis milling

For complex components that require 5-axis milling, we have milling machines with working areas up to 950 x 850 x 650 mm, with the option of simultaneous machining. For larger components, see bed-type and floor-type milling machines.

Horizontal milling

We have 4-axis horizontal machines with working areas up to 640 x 680 x 680 mm.

Vertical milling

We have 3-axis vertical machines with working areas up to 3048 x 1016 x 762 mm.

Turning

We carry out CNC turning with a working area up to 370 mm in diameter and 865 mm in length with powered tools. We also offer capstan turning with diameters up to 510 mm and length 1500 mm.